Safety Clearance Design Rules in PCB

Why we need to define PCB trace clearance and pad clearance values?

High voltage/high current designs carry safety requirements which need to be met by designers. Similarly, high speed designs need to have suppressed crosstalk in order to ensure signal integrity. The key design aspects that relate to both areas are your PCB trace clearance and pad clearance values. These design choices are critical for balancing safety, noise suppression, and manufacturability.

The IPC 2221 standards provide guidance for preventing ESD between conductors, but not all boards will need to meet this standard. Depending on the voltage and frequency of your signals (or edge rate for digital signals), you may need a different value for your PCB trace clearance. Here’s how to balance these two aspects of your PCB layout while also ensuring manufacturability.

Low Voltage (<15 V)

Under the IPC 2221 standards, the minimum PCB trace clearance (really, the clearance between any two conductors) is 0.1 mm for general purpose devices, or 4 mils. For power conversion devices, this minimum spacing is 0.13 mm, or 5.1 mils. These boards could hardly be considered “high voltage” and the conductor spacing in these boards starts to border on the HDI regime.

At these voltages, you may be working with digital signals, low frequency analog signals, or simply DC at moderate current. With digital signals, the typical rule is to simply follow the “3W” rule, WHERE the clearance between traces is triple the width of the trace. For a typical 50 Ohm controlled impedance microstrip, your trace width will be ~20 mils, thus the recommended trace spacing is 60 mils. You’re still well within IPC 2221 requirements with these traces, and your primary focus should be efficient routing and DFM. Even in the HDI regime, where you may need to route between fine-pitch pads in a BGA, you won’t need to worry about these voltage requirements as you’re generally working at 3.3 V or ~1 V.

When your routing is this tight, you’re still well within PCB trace clearance requirements below 15 V. Instead, focus on signal integrity and DFM.

High Voltage (>15 V)

At high DC voltage, the primary concern in choosing a PCB trace clearance value is preventing ESD and dendritic growth between exposed conductors. With high AC voltage, or with a switching regulator that outputs high current, you now have to worry about crosstalk, as well as ESD and dendritic growth. Crosstalk suppression guidelines still over-specify the required voltage spacing between conductors until you get to very high voltages.

To see how you might need to find a balance between IPC 2221 and crosstalk suppression, consider the following hypothetical situation. Suppose you have a controlled impedance microstrip (20 mil wide) near a high voltage AC line, or near traces running in/out of a high current DC regulator. If you follow the “3W” rule, the spacing between parallel microstrips and the nearby high voltage line should be 1.5 mm, or ~60 mils. This is more than enough to comply with IPC 2221 until the high voltage level reaches 180 V for power conversion devices, or 340 V for other high voltage products.

At high voltage, the concern is not so much a digital edge rate as is the frequency of a high voltage AC line. Any oscillating signal can induce a crosstalk signal in a nearby trace if the traces are close together; this is a known noise problem with high-voltage DC regulators and their downstream signal lines. At high output current, such crosstalk can induce unintended switching in high-speed digital components. It’s best to opt for greater spacing between a high voltage AC line and nearby DC or digital lines.

Other Safety clearance design rules in PCB

If the PCB area is really limited, a 4mil pitch is barely acceptable. Therefore, when designing, it is necessary to fully consider the adaptability between the components, the PCB product and the product shell, and the space structure, and reserve a safe distance for each target object to ensure that there is no conflict in space.

In PCB design, there are many places that need to consider the safety distance. Here, it is classified into two categories for the time being: one is electrical-related safety clearance, and the other is non-electrical-related safety clearance

Electrical related safety clearance

1. Spacing between wires

As far as the processing capabilities of mainstream PCB manufacturers are concerned, the minimum spacing between wires should not be less than 4mil. The minimum line distance is also the distance from trace to trace and trace to pad. From a production point of view, the larger the better if possible, the more common is 10mil.

2. Pad aperture and pad width

As far as the processing capabilities of mainstream PCB manufacturers are concerned, if the pad diameter is mechanically drilled, the minimum should not be less than 0.2mm, and if laser drilling is used, the minimum should not be less than 4mil. The aperture tolerance is slightly different depending on the plate, generally it can be controlled within 0.05mm, and the minimum pad width should not be less than 0.2mm.

3. The distance between the pad and the pad

As far as the processing capabilities of mainstream PCB manufacturers are concerned, the distance between pads and pads should not be less than 0.2mm.

4. The distance between the copper sheet and the board edge

The distance between the charged copper skin and the edge of the PCB board is preferably not less than 0.3mm. Set the spacing rules on the Design-Rules-Board outline

If it is a large area of copper, it usually needs to be retracted from the edge of the board, generally set to 20mil. In the PCB design and manufacturing industry, under normal circumstances, due to the mechanical considerations of the finished circuit board, or to avoid curling or electrical short-circuiting due to the exposed copper skin on the edge of the board, engineers often spread copper on a large area The block is shrunk by 20 mils relative to the edge of the board instead of spreading the copper to the edge of the board.

There are many ways to deal with this kind of copper shrinkage, such as drawing a keepout layer on the edge of the board, and then setting the distance between the copper paving and the keepout. Here is a simple method to set different safety distances for copper paving objects. For example, the safety distance of the whole board is set to 10mil, and the copper paving is set to 20mil, which can achieve the effect of 20mil shrinkage of the board edge, and also Remove the dead copper that may appear in the device.

Non-electrically related safety clearance

1. Character width, height and spacing

The text film cannot be changed during processing, but the character line width of D-CODE less than 0.22mm (8.66mil) is thickened to 0.22mm, that is, the character line width L=0.22mm (8.66mil).

The width of the entire character is W=1.0mm, the height of the entire character is H=1.2mm, and the spacing between the characters is D=0.2mm. When the text is smaller than the above standard, the processing and printing will be blurred.

2. Via-to-via spacing

Via hole (VIA) to via hole spacing (hole edge to hole edge) preferably greater than 8mil

3. Distance from silk screen to pad

The silk screen is not allowed to cover the pad. Because if the silk screen is covered with the pad, the silk screen will not be tinned during the tinning, Which will affect the component mounting. Generally, the board factory requires a space of 8mil to be reserved. If the PCB board has a limited area, a 4mil pitch is barely acceptable. If the silk screen accidentally covers the pad during design, the board factory will automatically eliminate the part of the silk screen left on the pad during manufacturing to ensure that the pad is tinned.

Of course, specific conditions are analyzed in design. Sometimes the silk screen is deliberately close to the pad, because when the two pads are very close, the middle silk screen can effectively prevent the solder connection from shorting during soldering. This situation is another matter

4. Mechanical 3D height and horizontal spacing

When mounting devices on the PCB, consider whether there will be conflicts with other mechanical structures in the horizontal direction and the height of the space. Therefore, when designing, it is necessary to fully consider the adaptability between the components, the PCB product and the product shell, and the space structure, and reserve a safe distance for each target object to ensure that there is no conflict in space.

Summary

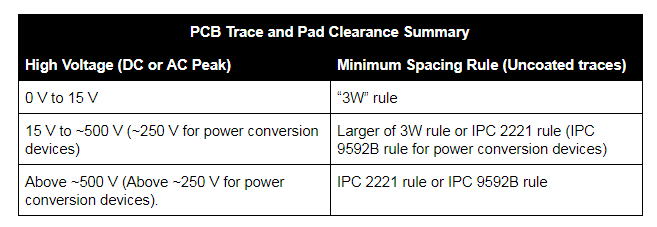

In general, we can define PCB trace and pad clearance rules into three different regimes based on voltage. And two regimes based on if it is electrical related safety clearance. In the two lower rows, be sure to calculate the required spacing using the IPC 2221 standard when determining which regime to work in. Note that, in the aforementioned article, your spacing can be made smaller when your traces are coated or are placed on inner layers.

Be sure to understand the difference between creepage and clearance in your design. Also, be sure to check that your traces will be wide enough to carry sufficient current without becoming too hot. This can be checked using the IPC 2152 nomograph.

Once you’ve figured out the best trace and pad clearances to use in your board, you need to encode these values as design rules in your ECAD software.

Capacités

Capacité PCB rigide

Capacité PCB flexible

Capacité d'assemblage PCB

Équipement PCB

Équipement d'assemblage PCB

Méthodes de paiement

Prix spéciaux

Transporteurs

Support pour amateurs

Certificat

Assistance clientèle

Suivez-nous

Tel: 1-905-339-2881

Email: [email protected] , [email protected]

Copyright Gold Phoenix PCB Co., Ltd. 2011 - 2023

Tel: 1-905-339-2881 Email: [email protected] , [email protected]

Système de contrôle qualité | Service produit

| Liens

Copyright Gold Phoenix PCB Co., Ltd. 2011 - 2023