Electronics are an integral part of our daily lives. Everything from our smart phones to our cars includes electronic components. At the heart of these electronics is the printed circuit board, also known as a PCB.

Most people recognize printed circuit boards when they see them. These are the small green chips covered in lines and copper parts you'll find at the heart of gutted electronic devices. Made with fiberglass, copper lines and other metal parts, these boards are held together with epoxy and insulated with a solder mask. This solder mask is WHERE that characteristic green color comes from.

However, have you ever observed those boards with components solidly stuck on? Never regard them as just decorations of a PCB board. An advanced circuit board won't be able to give its functionality until components are mounted on it. A PCB with components mounted on is called an assembled PCB and the manufacturing process is called PCB assembly or PCBA for short. The copper lines on bare board, called traces, electrically link connectors and components to each other. They run signals between these features, allowing the circuit board to function in a specifically designed way. These functions range from the simple to the complex, and yet the size of PCBs can be smaller than a thumbnail.

So how exactly are these devices made? The PCB assembly process is a simple one, consisting of several automated and manual steps. With each step of the process, a board manufacturer has both manual and automated options from which to choose. To help you better understand the PCBA process from start to finish, we've explained each step in detail below.

PCB Design Basics

The PCBA process always starts out with the most basic unit of the PCB: the base, which consists of several layers, and each one plays a significant role in the functionality of the final PCB. These alternating layers include:

· Substrate: This is the base material of a PCB. It gives the PCB its rigidity.

· Copper: A thin layer of conductive copper foil is added to each functional side of the PCB — on one side if it's a single-sided PCB, and on both sides if it's a double-sided PCB. This is the layer of copper traces.

· Solder mask: On top of the copper layer is the solder mask, which gives each PCB its characteristic green color. It insulates copper traces from unintentionally contacting other conductive materials, which could result in a short. The solder, in other words, keeps everything in its place. Holes in the solder mask are where solder is applied to attach components to the board. Solder mask is a vital step for smooth manufacturing of PCBA since it stops soldering from taking place on unwanted parts with shorts avoided.

· Silkscreen: A white silkscreen is the final layer on a PCB board. This layer adds labels to the PCB in the form of characters and symbols. This helps indicate the function of each component on the board.

These materials and components remain largely the same across all PCBs, with the exception of the substrate. The substrate material of a PCB changes according to the specific qualities — such as cost and bendability — each designer is looking for in their finished product.

The three primary PCB types include:

· Rigid PCB: The most common type of PCB base is a rigid one that accounts for majority of PCBAs. The solid core of a rigid PCB gives the board rigidity and thickness. These inflexible PCB bases consist of a few different materials. The most common is fiberglass, otherwise designated as "FR4". Less expensive PCBs are made with materials like epoxies or phenolics, though these are less durable than FR4.

· Flexible PCB: Flexible PCBs offer a bit more pliability than their more rigid counterparts. The material of these PCBs tends to be a bendable, high-temperature plastic like Kapton.

· Metal Core PCB: These boards are yet another alternative to the typical FR4 board. Made with a metal core, these boards tend to spread heat more efficiently than others. This helps dissipate heat and protect more heat-sensitive board components.

There are two types of mounting technologies are prevailing in the modern PCBA industry:

Surface Mount Technology: Sensitive components, some very small, such as resistors or diodes are placed automatically onto the surface of board. This is called SMD assembly, for surface mount device. Surface mount technology can be applied on small size components and integrated circuits (ICs). For example, PCBCart is capable of mounting package with min. size 01005, which is even smaller than the size of a pencil point.

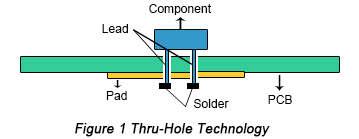

Thru-Hole Technology: works well on components with leads or wires that have to be mounted on board by plugging them through holes on board. The extra lead part has to be soldered on the other side of the board. This technology is applied on PCB assemblies containing large components such as capacitors, coils to be assembled.

Due to distinctions between THT and SMT, they have to go through different assembly processes as well. The following article will discuss other material and design considerations beyond the base of the PCB as they apply to the PCB assembly process in relation to THT, SMT and mixed technologies.

Before the Assembly Process

A few preparatory steps have to happen before real PCBA process even begins. This helps PCB manufacturers assess the functionality of a PCB design, and primarily includes a DFM check.

Most companies specializing in PCB assembly need the design file of the PCB to start out, along with any other design notes and specific requirements. This is so the PCB assembly company can check the PCB file for any issues that may affect the PCB's functionality or manufacturability. This is a design for manufacturability check, or DFM check, for short.

The DFM check looks at all the design specifications of a PCB. Specifically, this check looks for any missing, redundant or potentially problematic features. Any of these issues may severely and negatively influence the functionality of the final project. For example, one common PCB design flaw is leaving too little spacing between PCB components. This can result in shorts and other malfunctions.

By identifying potential problems before manufacturing begins, DFM checks can cut manufacturing costs and eliminate unforeseen expenses. This is because these checks cut down on the number of scrapped boards. As part of our commitment to quality at a low cost, DFM checks come standard with every PCBCart project order. PCBCart provides FREE DFM and DFA check with, however, priceless values because Valor DFM/DFA check PCBCart depends on is an automatic system contributing to high speed and accuracies.

Actual PCBA process steps

Step 1: Solder Paste Stenciling

The first step of PCB assembly is applying a solder paste to the board. This process is like screen-printing a shirt, except instead of a mask, a thin, stainless-steel stencil is placed over the PCB. This allows assemblers to apply solder paste only to certain parts of the would-be PCB. These parts are where components will sit in the finished PCB.

The solder paste itself is a greyish substance consisting of tiny balls of metal, also known as solder. The composition of these tiny metal balls is 96.5% tin, 3% silver and 0.5% copper. The solder paste mixes solder with a flux, which is a chemical designed help the solder melt and bond to a surface. Solder paste appears as a grey paste and must be applied to the board at exactly the right places and in precisely the right amounts.

In a professional PCBA line, a mechanical fixture holds the PCB and solder stencil in place. An applicator then places solder paste on the intended areas in precise amounts. The machine then spreads the paste across the stencil, applying it evenly to every open area. After removing the stencil, the solder paste remains in the intended locations.

Step 2: Pick and Place

After applying the solder paste to the PCB board, the PCBA process moves on to the pick and place machine, a robotic device places surface mount components, or SMDs, on a prepared PCB. SMDs account for most non-connector components on PCBs today. These SMDs are then soldered on to the surface of the board in the next step of PCBA process.

Traditionally, this was a manual process done with a pair of tweezers, in which assemblers had to pick and place components by hand. These days, thankfully, this step is an automated process among PCB manufacturers. This shift occurred largely because machines tend to be more accurate and more consistent than humans. While humans can work quickly, fatigue and eyestrain tends to set in after a few hours working with such small components. Machines work around the clock without such fatigue.

The device starts the pick and place process by picking up a PCB board with a vacuum grip and moving it to the pick and place station. The robot then orients the PCB at the station and begins applying the SMTs to the PCB surface. These components are placed on top of the soldering paste in preprogrammed locations.

Section

Printed Circuit Boards Assembly (PCBA) Process_1

Printed Circuit Boards Assembly (PCBA) Process_2

Capacités

Capacité PCB rigide

Capacité PCB flexible

Capacité d'assemblage PCB

Équipement PCB

Équipement d'assemblage PCB

Méthodes de paiement

Prix spéciaux

Transporteurs

Support pour amateurs

Certificat

Assistance clientèle

Suivez-nous

Tel: 1-905-339-2881

Email: [email protected] , [email protected]

Copyright Gold Phoenix PCB Co., Ltd. 2011 - 2023

Tel: 1-905-339-2881 Email: [email protected] , [email protected]

Système de contrôle qualité | Service produit

| Liens

Copyright Gold Phoenix PCB Co., Ltd. 2011 - 2023